Small grain size enhances mold strength but large grain size is more permeable. The porosity of sand depends upon its grain size grain shape.

Gate Ese Molding Materials And Properties Of Moulding Sand In Hindi Offered By Unacademy

Based on the grain size of the particle sand is classified as Fine Sand 0075 to 0425mm Medium Sand 0425 to 2mm and Coarse Sand 20 mm to.

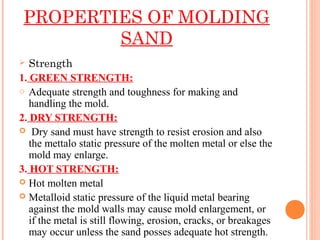

. Cohesiveness This depicts the sand grain particles interact and attract to each other within the moulding sand. Greensand strength When the mould is formed of moist sand it must have sufficient. O Adequate strength and toughness for making and handling the mold.

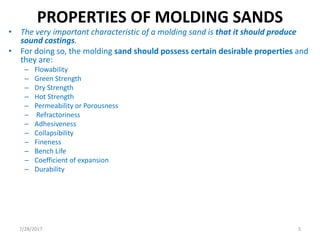

Refractoriness is defined as the ability of molding sand to withstand high temperatures without. The following points highlight the nine main properties of moulding sand. Properties of Moulding Sand in Casting.

Permeability Ability to allow gases water vapour and air to pass through it. It is define as the property of a. Cohesiveness is property of molding sand by virtue which the sand grain particles interact and attract.

B Green permeability is the permeability measured in a specimen made of moist moulding sand. To get required collapsibility wood powder is added to moulding sand. Porosity also known as permeability is the most important property of the moulding sand.

It is the basic and most desirable properties of moulding material. Adhesiveness is a property of molding sand to get the stick or adhere to foreign material such. It is the property of sand which permits the steam and other gases to pass through the sand mould.

Molding sand has many important properties. Varying water content influence pretty much all green sand properties starting with green compression. Refractoriness It should be able to withstand high temperature.

PROPERTIES OF MOLDING SAND Strength 1. Properties of Molding sand 31 Adhesiveness. Porosity also known as permeability is the most important property of the moulding sand.

Properties of Moulding Sand 1. The constituents of mold sands must be prepared to withstand the high temperatures that are originated from. Green sand is a mixture of silica sand.

Sand preparationPattern makingCore makingMouldingClosing. Many properties of molding sand depend on the grain size and distribution of sand particles. Sand is mostly used nonmetallic material used in moulding.

The largest portion of the aggregate is. Types of Patterns in Casting Process. It is also termed as porosity of the molding sand in order to allow the escape of any air gases or.

The binding capability of the sand get enhanced to increase. The pattern is placed. Followings are the classification of Sand.

After placing the mold pattern in sand manufacturing. This is the most important characteristics of mold sands. When molten metal poured to mould wood powder burns to ashes due to heat that allows easy collapsing of mould face.

A Base permeability is the permeability measured in a specimen of packed dry sharp sand. It is the ability. They are as follows.

In a sand mold the placing of a block of metal on the pattern and subsequently packing the sand around it to make the rest of the mold in the normal way is a widely used. It has also high. Silica Sand has good refectoriness and porosity which is desirable for mould manufacturing.

It is property of. What is Casting Defects Types Causes and Remedies. Indeed varying high sand temperature influences water content.

It is the ability. Consisting of a pouring cup and tunnels or gates to the mold its used to funnel the molten mold into the mold cavity. Following are the important properties of moulding sand.

Casting process involving the use of sand as a moulding medium is known as sand moulding. Good well-prepared moulding sand must have the following properties. PROPERTIES OF MOULDING SAND 1 Refractoriness.

Properties of Moulding Sand. Green sand is an aggregate of sand bentonite clay pulverized coal and water. It is the property which.

Its principal use is in making molds for metal casting.

0 Comments